Loudspeaker Thiele/Small

Parameter Extraction

Here we extract basic free air

Theile/Small parameters from the complex impedance curve of a 10” low

frequency driver. These parameters may be used to verify the

manufacturers published specifications and provide the basis for

enclosure design.

Two external resistors are required to

perform this measurement. First a resistor (R1), to establish a constant

current in the circuit is required. The precision and value of this resistor

is not critical. However, if it is too low (< 30Ω), its purpose

is defeated and if it is too high (> 5kΩ) noise immunity of the

circuit will be compromised. Secondly a precision reference

resistor (R2), whose value is known to two decimal points, is required.

This provides the software with a known reference so that it can

accurately plot the absolute value of the driver impedance in the

spectrum analyzer.

We will use "32768_MLS_Impedance_Measurement.process"

to perform the measurement. This process ships with the release version

of this product. It consists of four modules. The first is the signal

generator, which generates a 32768 length MLS stimulus to excite the DUT.

Second is the SoundIO module, which plays the stimulus and records the

response of the driver. Third is the Oscilloscope module, which allows us

to view the time domain response of the driver. Finally is the Spectrum

Analyzer, which performs an FHT/ FFT on the time domain data and allows

us to view impedance vs. frequency and phase vs. frequency graphs.

You must have a dual channel, duplex

sound card to perform this measurement.

1. Measure the value of the reference

resistor using a precision ohmmeter or DC resistance bridge. Our

reference measures in at 10.067Ω.

2. Measure the DC resistance of the

drivers voice coil (RE) to the nearest 0.1Ω. Use a

precision ohmmeter or bridge. Our voice coil measures in at 6.89Ω.

This application cannot measure the DC resistance of the drivers voice

coil directly. This is due to the fact that most sound cards are AC

coupled, that is they have a capacitor between their internal amplifier

and their output jack, and thus do not pass DC current. Driver voice coil

resistance can be measured using very low frequency sine waves (< 1Hz)

and a series precision resistance but most sound cards cannot reliably

reproduce such frequencies. If you have a 1.5 volt battery and voltmeter

available you can wire the loudspeaker and the precision resistor in

series across the battery terminals and calculate the voice coil

resistance using the following equations.

3. Suspend the driver vertically about

half way between the ceiling and the floor using a piece of wire or

twine. Do not place the driver horizontally on a table or other

reflective surface. This will result in cone pre-loading that will cause

errors. Reflections from any nearby surface will cause response ripples

in the impedance curve.

4. Wire the circuit as shown in Figure

1. Use short, low resistance or shielded wiring. Note that many

sound cards speaker outputs have more swing than their respective line

inputs.

Figure 1: Thiele/Small Extraction Process Calibration Wiring

5. If you are running Windows 7 or 8 or

Vista you must disable all sound effects applied to your sound card.

Right click the sound icon on the windows task bar and select Playback

devices from the popup menu that appears. Select the sound card you

intend to use from the "Select a playback device below to modify its

settings" listbox and press the Properties button. Select the

Enhancements tab and check the Disable all Sound effects

checkbox. Press the OK button.

Figure 2: Windows 7/Vista Playback Enhancements Disabled

6. Open " C:\Users\Public\Documents\Sonic

Beacon\Sonic Beacon\32768_MLS_Impedance_Measurement.process"

from the applications File…Open… menu. Press OK if the

“No Compatible Calibration File Present” message box appears.

7. Open the FFT Options dialog from

the applications Options…FFT… menu and ensure the FFT Size

is 32768. Press OK in the FFT Options dialog box. Press OK

when the “No Compatible Calibration File Present” message box

appears.

8. You need to adjust the level of your

selected sound card recording path. If you are running Windows 7 or 8 or

Vista right click the sound icon on the windows task bar and select Recording

devices from the popup menu that appears. Double click the selected

sound card in the Sound dialog box Recording tab. Select the Levels

tab and adjust the slider to its one-quarter setting. Press the OK

button. If you are running XP or below; select the Levels tab

Press the Open Mixer button the SoundIO modules Options

group. Select Options… Properties… Choose your sound card from the

Mixer Device and press the Recording radio button in the Adjust

Volume for group. Press the OK button. Deselect all Record

Control mixer paths except the Line In. Adjust the Line In

mixer slider to its one-quarter setting and equalize its balance slider.

9. You

need to adjust the output level of your selected sound cards playback

path. If you are running Windows 7 or 8 or Vista select the Playback

tab of the Sound dialog box and double click the selected sound card.

Select the Levels tab and adjust the Line In to its 25% setting. Otherwise

if you are using XP or lower select Options… Properties… Press the

Playback radio button in the Adjust Volume for group. Press

the OK button. Mute all Playback mixer gain settings except

the Volume Control and the Wave Out. Equalize the Volume

Control and the Wave Out mixer balance sliders. Adjust the Volume

Control and the Wave mixer sliders to their one-quarter

settings.

10. Press the applications Run button. You

should be able to see the MLS sequence in the oscilloscope module as

shown in Figure 3. If a SoundIO “No data in record buffer” message

appears first check that your wiring conforms to Figure 1. If it is

correct, increase the mixers Playback Volume Control and Wave

Out sliders or Recording Line controls.

Figure 3: Thiele/Small Extraction Process MLS Sequence Setup

11. If all three controls are at maximum you may

reduce the level at which the sound card triggers. When in Record/Play

mode, the SoundIO module sends a record buffer to the sound card that

is 1.4 longer than required. This is to compensate for various system

delays. It then scans the buffer for the first level that is greater than

the trigger level. It then marks this point as the beginning of the

record and returns the remainder of the record (up to the number of

samples required for the selected FFT size) to the application. This is

the record that the modules processes and sends to subsequent modules.

Trigger level is expressed in terms of percentage full scale. Check the

value in the Trig. Level (%F.S.) in the SoundIO Trigger

Parameters group. If it is greater than 20 select 10 in

the combo box. Press the Run button and check the oscilloscope

display again. You can reduce this value to as low as 1%. This

corresponds to 1% of the sound card full-scale output. You can estimate

the length of the buffer that is sent to the sound card for a given FFT

Size from the equation below.

If

you know the full scale output voltage of your sound card, you can

estimate the level that causes the SoundIO module to trigger from the equation

below. Sound cards have a typical input swing ranging from +0.5 to

+2.0 volts.

Once

you have a valid trigger, adjust the Play Control and the Wave

sliders so that the signal in the oscilloscope display is not clipped (as

in Figure 3).

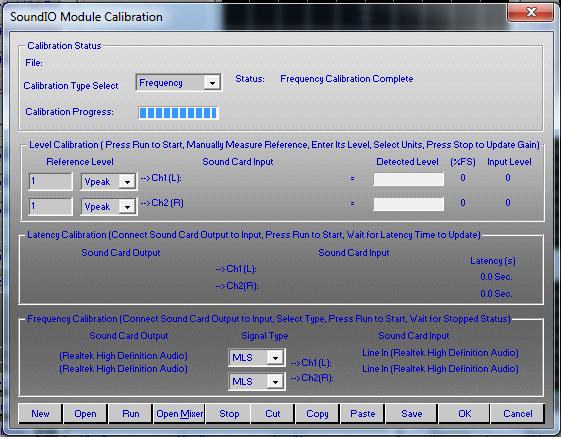

13. You now need to calibrate the frequency response

curve of the sound card if you do not already have a valid calibration

file loaded for the input and output devices selected in the SoundIO

module. Level and Latency calibration are not required for complex

impedance measurement. Press the Calibration button in the SoundIO

module. The SoundIO Module Calibration dialog box will open..

14. Select Frequency from the Calibration

Type Select: combo box in the Calibration Status group box.

Select MLS from the Signal Type combo box in the Frequency

Calibration group box.

15. Press the Run button and wait for the Frequency

Calibration Complete status message to appear. If a “No data in

record buffer” message box appears Press the Open Mixer button

and increase the applications output level slider. The SoundIO modules

input device level may also be increased by right clicking on the Windows

Task Bar Sound icon and selecting the Recording and Levels

and adjusting the devices slider. Frequency calibration may be restarted by

pressing the Run button. If successful, the calibration dialog should

look as in Figure 4. The Calibration Progress bar may not update in

certain versions of Windows.

Figure 4: Thiele/Small Extraction Process Calibration Dialog

after Auto Calibration

17. Now rewire the circuit as shown in Figure 5.

Figure 5: Thiele/Small Extraction Process Test Wiring

18. Change the Spectrum Analyzers XAxis Selection to Log10.

Set the Stop Frequency to 689Hz using the Stop: Dn button

in the XAxis group. Change the Y-Axis Selection and scale to |Z|

and 10 ohms/div respectively. Enter the exact value of the

reference resistor wired between Ch1 Line-In and Ch2 Line-In in the Ref1:

edit box in the spectrum analyzer. Check the Apply Freq Cal

checkbox. Change the Averaging factor to 4 in the Avg:

combo box of in the spectrum analyzer. This will help smooth the low

frequency results.

Figure 6: Thiele/Small Extraction Process Spectrum Analyzer

Module Settings

19. Press the Run button on the application

toolbar and observe the trace in the spectrum analyzer. The impedance and

phase appear in channels one and two respectively.

Figure 7: Thiele/Small Extraction Process Spectrum Analyzer Module

With Driver Impedance and Phase Plots

20. Find the maximum impedance in the spectrum

analyzer and record it (Rmax) and the frequency at which it

occurred (fSA). Pressing the right mouse button and dragging it

past the impedance peak will show the driver resonant frequency and peak

impedance. Our Rmax = 54.93 ohms and our fSA = 40.8

Hz.

21. Calculate r0 using the following

equation.

21. Calculate Rx using the following equation. Use the

markers to find the frequencies f1 and f2 on the

impedance curve (above and below fSA) that corresponds exactly

to the impedance value of RX. Our frequencies are f1

= 32.9Hz and f2 = 50.7Hz respectively.

22. Check that the square roots of the product of the

frequencies (f1 and f2) are within 1 Hz of the measured fSA.

Use the following equation.

23. Now calculate the mechanical Q of the driver at

its free air resonant frequency (QMS) as follows:

24. Now calculate the electrical Q of the driver at

its free air resonant frequency (QES) as follows:

25. Now calculate the total Q of the driver at its

free air resonant frequency (QTS) as follows:

Below is a table showing the measured

and calculated Thiele/Small parameters using two methods. First the

constant current method above (column 2) and second the voltage divider

method (see setup in Figure 8) using three different values of

reference resistance (columns 3 to 5). They are 10.07Ω, 100.77Ω

and 994.43Ω respectively. When using the Voltage Divider method

accuracy depends strongly upon the assumption that RREF is much

larger than the driver impedance. As can be seen from Table 1 the

measured value of the driver peak impedance at its resonant frequency (Rmax)

decreases as the value of RREF increases. Hence the

calculated values of QMS, QES and QT (which

are inversely proportional to RMAX) will decrease as RREF

increases.

Figure 8: Thiele/Small Extraction Process Voltage Divider

Method Test Wiring

|

Reference

Resistor

|

10.067Ω

Const.

Current

|

10.07Ω

Voltage

Divider

|

100.77Ω

Voltage

Divider

|

994.43Ω

Voltage

Divider

|

|

fSA(meas)

|

40.8Hz

|

40.8Hz

|

40.8Hz

|

40.8Hz

|

|

RMAX(meas)

|

54.93Ω

|

62.41Ω

|

55.41Ω

|

54.63Ω

|

|

RE(meas)

|

6.89Ω

|

6.89Ω

|

6.89Ω

|

6.89Ω

|

|

r0(calc)

|

7.97Ω

|

9.05Ω

|

8.04Ω

|

7.93Ω

|

|

RX(calc)

|

19.45Ω

|

20.72Ω

|

19.53Ω

|

19.40Ω

|

|

f1(meas)

|

32.9Hz

|

33.8Hz

|

32.4Hz

|

33.3Hz

|

|

f2(meas)

|

50.7Hz

|

48.7Hz

|

50.7Hz

|

50.0Hz

|

|

QMS(calc)

|

6.47

|

8.23

|

6.32

|

6.87

|

|

QES(calc)

|

0.92

|

1.23

|

0.90

|

0.99

|

|

QTS(calc)

|

0.81

|

0.91

|

0.79

|

0.86

|

Table 1: Thiele/Small Extraction Process Constant Current

Verses Voltage Divider Method Test Results

21. Now add a mass (such as back to back ceramic disk magnets

or blobs of silly putty or talc) symmetrically about the cone apex. This

will lower the drivers resonant frequency by increasing its cone mass.

The resonant frequency of the driver must be lowered by at least 25% in

order for this to work. In our case this would be a reduction of about 10

Hz. Press the Run button on the application toolbar and observe

the trace in the spectrum analyzer. If the resonant frequency is not

lowered by about 25% add more mass and repeat. Never add a mass greater

than the cone mass. Remove the mass and weigh it to 0.1gram accuracy. You

will need a good scale to do this. The total mass of our silly putty is

13.50 grams Note that paper cones may be damaged when removing silly

putty. Notice the response ripples in the curves due to cone interaction

with the added mass. The better distributed the mass the lower amplitude

of the ripples.

Figure 9: Impedance and Phase Plots of Driver with Added

Mass

22. Find the drivers new resonant frequency on the

added mass impedance curve. Ours is now about 31.1Hz. Then compute the

mechanical mass of the driver cone assembly (including air load) (MMS

in kilograms) as follows:

23. The mechanical compliance of a drivers suspension

is the inverse of how much force (Force = mass x acceleration) it takes

to push the cone per unit distance (per meter). The lower the compliance

the harder it is to push the cone back into the drivers’ magnetic

assembly. Compliance is inversely proportional to drivers’ cone mass and

it free air resonant frequency. This makes sense because the greater a

given mass, the lower its resonant frequency and the harder it is to push

around. Compute the drivers mechanical compliance (CMS) as

follows:

30. Measure the driver cone effective surface area (SD

in meters2). Measure the diameter of the driver cone including

one half of the surround. Ours is a 10” driver so our effective diameter

is about 8.25”. Thus our radius (effective diameter / 2) is 4.125”.

Converting to metric we get 4.125” x 1m / 39.37” = 0.105m. Thus:

29. The free air resonant frequency of a driver is

inversely proportional to the square root of its compliance and its total

mass. This mass includes the mass of the cone, the voice coil assembly,

the dust cap and about half of the surround and spider. The surrounding

air has mass as well and so it exerts a pressure on the cone. This lowers

the resonant frequency. The mass is proportional to air density (p =

1.18kg/m3 @ 20C @ sea level) and the radius of the cone (0.105m). It

ranges from 0.001kg for a 3" driver to about 0.027kg for an 18"

driver. When the driver is suspended in free air this effective

mass (MM1) can be calculated as follows.

30. The mass of the driver cone assembly(MMD)

excluding air load is:

31. We can now check the free air driver resonant

frequency (fSA). The result is very close to our measured

value of 40.8Hz.

32. A driver in an enclosed box is a piston pushing

against a volume of compressible air. The larger the cone and the smaller

the air volume the harder it is for the cone to move back and forth

against the enclosed volume of air. The enclosed volume of air that has

the same stiffness as the driver’s suspension system when compressed by a

piston the same diameter as the driver cone is known as VAS.

It is usually measured in manufacturer’s data sheets as liters of air at

standard temperature (20C) and pressure (sea level). However 1 liter of

air at standard temperature and pressure occupies 1000 liters The volume

of air having the same acoustic compliance as the driver suspension (VAS

in meters3) is calculated as follows:

where: p = the density of air (1.18 kg/m3 at

20°C @ sea level)

and: c = speed of sound (344.5 m/s at 20°C @ sea level)

33. From these basic parameters we can determine an

enclosure type (baffle, closed or vented box). Calculating the drivers

Efficiency Band-width Product (EBP) will give us an idea of the type of

enclosure to design. If the EBP is less than 50 a sealed enclosure might

be more suitable. If greater a vented enclosure should be designed. As

can be seen our driver should go into a closed box.

34. When a driver is placed in a closed box it behaves

like another driver with a heavier cone and a stiffer suspension. Its

resonant frequency is lowered and its Q is raised. In order to calculate

the driver Bl product (Bl), efficiency (n0) and power

sensitivity (Sp) we need to know a little about the intended enclosure.

Calculation of these parameters requires that we know the resonant

frequency of the driver (fSB) when it is mounted in the

enclosure. We will design a sealed enclosure for the driver with a total

system QTC of 1.0. This system will have warm robust lower

end. The system response will be boosted by about 1.25 dB near the

cut-off frequency. First we calculate system alpha as follows:

35. The estimated system resonance may be calculated

as follows:

36. The required box volume may be calculated as

follows:

37. In order to calculate the resonant frequency of

the driver (fSB) when it is mounted in the enclosure we need

to know the mass reactance loading on both the front and rear of the

cone. To calculate the mass reactance loading for the front of the driver

cone (MMR[front]) in a box less than 8ft3:

38. The equation for the effective mass loading on the

rear of the cone is

39. To solve this equation we need to know the value

of Km For rectangular baffles Km approximately

equals:

40. To solve this equation we need to know the value

of B. B is the ratio of the cone area (SD) to the front baffle

area (height x width). We will design a rectangular box with side

dimensions (height, width and depth) in the ratio of 1.6:1.2:1. Thus to

calculate the depth of the box from which all other dimensions can be

derived from:

41. Thus the ratio (B) of the cone area (SD)

to the front baffle area (h x w).

40. So Km equates to:

30. So the effective mass, reactance loading on the

rear of the cone (MMR[rear]) is:

31. In order to find the mechanical mass of the driver

excluding air load (MMD) we subtract the mass, reactance loading

of the drivers piston mounted in free air (MM1) from the total

mass, reactance of the driver cone assembly including air load (MMS)

41. Now we add the mechanical mass of the driver

excluding air load (MMD) plus the mass, reactance loading for

the front of the driver cone (MMR[front]) plus the effective

mass, reactance loading on the rear of the cone (MMR[rear]) to

get the mechanical mass of the driver cone assembly excluding air load

(M'MS) when it is mounted in the box.

42. Now we can find the resonant frequency (fSB)

and Q (QTB) of the driver mounted in the enclosure. Notice

that the driver resonant frequency is lowered (from fSA = 40.8

Hz to fSB = 38.4 Hz) and its Q is raised (from QTS

= 0.81 to QTB = 0.86), just as predicted.

43. The Bl product is a measure of the driver motor

strength. It is equal to the field strength of the driver magnet

multiplied by the length of the voice coil wire in the field. Large,

heavy cones with large excursion requirements (Xmax) need

strong motor systems to control harmonic distortion. As more of the voice

coil moves out of the pole piece gap it takes more electrical energy to

move the cone a given distance. From the corrected resonant frequency (fSB)

the Bl product (Bl) of the 10” low frequency driver may be calculated as

follows:

44. Efficiency defines how much acoustic power per electrical

watt of input the driver can produce. It is used to match components in

multi driver systems. Then also from the corrected resonant frequency (fSB)

the half plane, mid-band efficiency (n0) (full-space

efficiency is 3dB less) of the 10” low frequency driver may be calculated

as follows:

45. Reference power sensitivity is the sound pressure level

produced by the driver when mounted on a large baffle at 1 meter with an

electrical input of 1 Watt. From the corrected mid-band efficiency (n0)

the power sensitivity of the 10” low frequency driver can be calculated

as follows:

|